Rice Husk Baling Machine

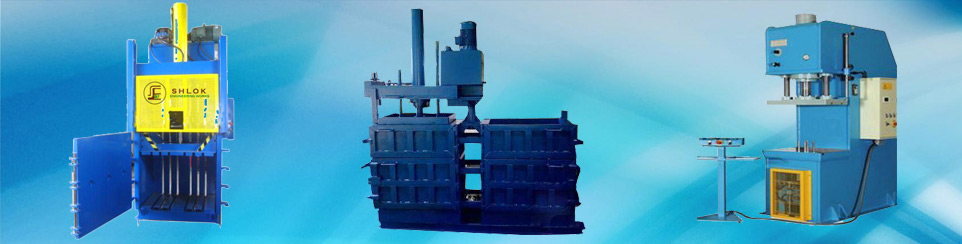

Vertical Bailing and Bagging Machine for Rice Husk

Vertical Bailing and Bagging Machine for Rice Husk offered come backed by advanced technology support so as to offer ideal compression support during baling process and well manage the packaging requirements of small, loose materials in a more convenient and compact manner. As vertical balers, these efficiently handle the compacting and baling operations so as to ensure easier process handling. Some of its features include allows bailing of all types of loose material, suitable for use in areas like animal bedding material factories, pet food factories, plant fertilizer factories and others; provide for efficient functional performance, allows production of up to 30 bales per hour based on material that is being baled with aggregate bale weight of 20 to 30 Kgs, provide for versatile operation support among others.

Vertical Bailing and Bagging Machine for Rice Husk offered come backed by advanced technology support so as to offer ideal compression support during baling process and well manage the packaging requirements of small, loose materials in a more convenient and compact manner. As vertical balers, these efficiently handle the compacting and baling operations so as to ensure easier process handling. Some of its features include allows bailing of all types of loose material, suitable for use in areas like animal bedding material factories, pet food factories, plant fertilizer factories and others; provide for efficient functional performance, allows production of up to 30 bales per hour based on material that is being baled with aggregate bale weight of 20 to 30 Kgs, provide for versatile operation support among others.

Baling Applications:

- wood shavings

- Chopped straw

- Paper shreds

- Chaff

- Rice hull

- Film

- Cotton seeds

- Rags

- Peanut shells

- Mineral cotton fiber and other similar loose materials.

View horizontal baler for bagging and baling solution

Choose from our existing models or contact us today for a customized model to meet your specific baling demands.

Main FeaturesAutomatic Baling and Bale Ejecting

Which promotes work efficiency and saves labor cost

Availability for Bagging

Enables the compacted bales to be ejected directly to the bag at the outlet of the chamber

One Button Operation

Makes baling, bale ejecting, and bagging a continuous process. This saves time, and it also saves money, as one person can do the job. View image

One-time Material Feeding

For increasing baling productivity.

Horizontal Bailing and Bagging Machine for Rice Husk

Horizontal Bailing and Bagging Machine for Rice Husk offeredcome designed and developed using latest technology support so as to effectively handle the horizontal baling and bagging operations of different types of loose materials like rags, peanut shells, sawdust, wood chips, rice hulls, cotton seeds and others. Further, these come with automatic feeding, baling, compacting and bagging support so as to provide for precise working performance. Some of its features include latest PLC control support for smooth and efficient handling of operations, provides for uniform bale quality, comes with easy to use handling interface, come with sensor switch on hopper for added work safety, allows quick packaging of bales in plastic/woven bags, production capacity of up to 60 bales in an hour with aggregate bale weight of 40 Kgs at 28*16*12 inches in size; ideally suited for use in textile recycling facilities, rag bale exporters, pet food factories, animal bedding material factories and other areas.

Horizontal Bailing and Bagging Machine for Rice Husk offeredcome designed and developed using latest technology support so as to effectively handle the horizontal baling and bagging operations of different types of loose materials like rags, peanut shells, sawdust, wood chips, rice hulls, cotton seeds and others. Further, these come with automatic feeding, baling, compacting and bagging support so as to provide for precise working performance. Some of its features include latest PLC control support for smooth and efficient handling of operations, provides for uniform bale quality, comes with easy to use handling interface, come with sensor switch on hopper for added work safety, allows quick packaging of bales in plastic/woven bags, production capacity of up to 60 bales in an hour with aggregate bale weight of 40 Kgs at 28*16*12 inches in size; ideally suited for use in textile recycling facilities, rag bale exporters, pet food factories, animal bedding material factories and other areas.

Baling Applications:

- wood shavings

- Chopped straw

- Paper shreds

- Chaff

- Rice hull

- Film

- Cotton seeds

- Rags

- Peanut shells

- Mineral cotton fiber and other similar loose materials.

Choose from the horizontal baling models below, or contact us for a customized baling solution that will fit your unique baling needs.

Main Features

PLC Control System

which simplifies the operation and promotes accuracy.

One Button Operation

makes baling, bale ejecting and bagging a continuous, efficient process, saving you both time and money. View image

Automatic Feeding Conveyor can be Equipped

for further enhancing feeding speed and maximizing throughput.

Sensor Switch on Hopper

for controlling bales under your desired weight