Pet Bottle Baling Machine

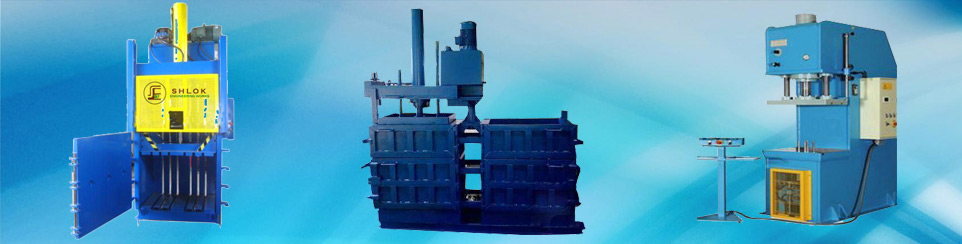

Vertical Pet Bottle Baler

This Vertical Pet Bottle Baler is designed for long stroke pressing. It is a must-have piece of equipment for any plastic or can recycling operation, and is ideal for crushing hollow products such as PET bottles and aluminum cans into tight, compact bales for easy handling, storage, and transporttion.

This Vertical Pet Bottle Baler is designed for long stroke pressing. It is a must-have piece of equipment for any plastic or can recycling operation, and is ideal for crushing hollow products such as PET bottles and aluminum cans into tight, compact bales for easy handling, storage, and transporttion.

Specifications:

- Volume reduction ratio : 25:1

- Can produce up to 400 Kgs. bales

Applications:

- PET bottles

- Disposable plastic tableware

- HDPE/PP jars

- Pop / soda cans

Features:

- Long Ram : Ensures full compaction of every hollow article in the bale. This is especially important with aluminum cans and similar.

- Liquid Drainage Tray : For collecting and draining out the residual liquid in the containers. This is a must-have for any baling of containers that contained liquids.

- Auto Chain Bale Ejector : For automatically ejecting bales out of the chamber through the lifting force of the chain.

- Fixed Retainer Claws : Prevents the compacted material from rebounding

Horizontal Pet Bottle Baler

Horizontal Pet Bottle Baler from Shlok also known as semi-automatic horizontal balers are used for pressing various material including both solid material and hollow plastic material. This machine is a good option for facilities that handle no more than 2tons volume of waste per hour and also with relatively low labor cost.

Horizontal Pet Bottle Baler from Shlok also known as semi-automatic horizontal balers are used for pressing various material including both solid material and hollow plastic material. This machine is a good option for facilities that handle no more than 2tons volume of waste per hour and also with relatively low labor cost.

Applications:

- Cardboard

- Paper

- PET bottles

- PP/HDPE containers

- Textile waste

- Film

- Packing material

- Fiber

- Disposable plastic tableware

Features:

- Electric Controlled : For easy operation, simply by operating on buttons and switches to fulfill platen moving and bale ejecting

- Hydraulic Lifting Chamber Door : For automatically lifting up to let the bales come out, which promotes operation efficiency and increase output

- Automatic Feeding Conveyor is Optional : For continuous feeding material, and with the help of sensors and conveyor will automatically start or stop when the material below or certain position on hopper. This enhances feeding speed and maximize throughput

- Horizontal Cutter on Feeding Mouth : For cutting off the excessive material to prevent it from being stuck feeding mouth