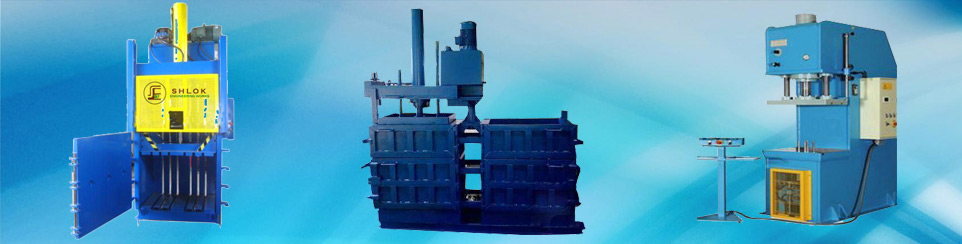

Hydraulic Scrap Baling Press

Double Action Scrap Baling Machine Manual Door

Overview Scrap balers are used for reducing the scrap materials in two dimensions by using hydraulic force from two different angles. The bale density is slightly less than triple compression baler. The balers has one cylinder fixed in horizontal position. Vertical reduction usually take place by hydraulic pressure on the lid cylinder. The horizontal cylinder presses the scrap against the ejection door of the baler. This door can be raised or opened hydraulically after the process of baling is complete. The scrap bundle is then removed from the chamber by horizontal cylinder.

Overview Scrap balers are used for reducing the scrap materials in two dimensions by using hydraulic force from two different angles. The bale density is slightly less than triple compression baler. The balers has one cylinder fixed in horizontal position. Vertical reduction usually take place by hydraulic pressure on the lid cylinder. The horizontal cylinder presses the scrap against the ejection door of the baler. This door can be raised or opened hydraulically after the process of baling is complete. The scrap bundle is then removed from the chamber by horizontal cylinder.

* Scrap Feeding Hopper can also be provided on customer's request.

Salient Features:

-

Option for Hand Lever operated as well as PLC Controlled Scrap Balers

-

High Speed & fully automatic Balers can be manufactured

-

Equipped with all the safety features

-

CE Marking on the balers can also be arranged on extra cost

-

Lower energy consumption with increased rate of production

-

Requires minimum maintenance

-

Reliable hydraulic system & power pack ensured by the use of imported valves of reputed make

-

Valves are easily interchangeable

-

Lower cost per ton than any other baler

-

Ease of operation

-

Each Baler is rigorously tested prior to the dispatch

-

Third party Inspection can also be arranged.

-

Spare parts are easily available across the globe.

-

Heavy duty construction of the balers.

-

Can be customized as per the specifications of the clients.

-

Single compact unit mounted over I –Beam (girders)

-

Hydraulic Accessories are provided to avoid accident.

-

No major civil foundation is required.

-

Replaceable wear resistance plate for long life of the baling chamber.

- Shearing blades on the edges of the chamber and door to shear excess and oversize scrap.

- Heat exchanger (optional) for keeping oil cool

Double Action Scrap Baling Machine Top Ejection

Scrap balers are used for reducing the scrap materials in two dimensions by using hydraulic force from two different angles. The bale density is slightly less than triple compression baler. The balers has one cylinder fixed in horizontal position. Vertical reduction usually take place by hydraulic pressure on the lid cylinder. The horizontal cylinder presses the scrap against the ejection door of the baler. This door can be raised or opened hydraulically after the process of baling is complete. The scrap bundle is then removed from the chamber by horizontal cylinder.

Scrap balers are used for reducing the scrap materials in two dimensions by using hydraulic force from two different angles. The bale density is slightly less than triple compression baler. The balers has one cylinder fixed in horizontal position. Vertical reduction usually take place by hydraulic pressure on the lid cylinder. The horizontal cylinder presses the scrap against the ejection door of the baler. This door can be raised or opened hydraulically after the process of baling is complete. The scrap bundle is then removed from the chamber by horizontal cylinder.

Scrap Feeding Hopper can also be provided on customer's request.

Salient Features:

-

Option for Hand Lever operated as well as PLC Controlled Scrap Balers

-

High Speed & fully automatic Balers can be manufactured

-

Equipped with all the safety features

-

CE Marking on the balers can also be arranged on extra cost

-

Lower energy consumption with increased rate of production

-

Requires minimum maintenance

-

Reliable hydraulic system & power pack ensured by the use of imported valves of reputed make

-

Valves are easily interchangeable

-

Lower cost per ton than any other baler

-

Ease of operation

-

Each Baler is rigorously tested prior to the dispatch

-

Third party Inspection can also be arranged.

-

Spare parts are easily available across the globe.

-

Heavy duty construction of the balers.

-

Can be customized as per the specifications of the clients.

-

Single compact unit mounted over I –Beam (girders)

-

Hydraulic Accessories are provided to avoid accident.

-

No major civil foundation is required.

-

Replaceable wear resistance plate for long life of the baling chamber.

-

Shearing blades on the edges of the chamber and door to shear excess and oversize scrap.

-

Heat exchanger (optional) for keeping oil cool

Triple Action Scrap Baling Machine

Triple compression balers are used for reducing three dimensions of the scrap material by using hydraulic force from three different angles. The two horizontal cylinders are arranged at right angles to each other. Vertical reduction generally takes place by hydraulic pressure on the lid cylinder. One of the horizontal cylinders presses the scrap against the ejection door of the baler. This door is raised hydraulically after baling is complete. The bundle is then removed from the chamber by horizontal cylinder.

Triple compression balers are used for reducing three dimensions of the scrap material by using hydraulic force from three different angles. The two horizontal cylinders are arranged at right angles to each other. Vertical reduction generally takes place by hydraulic pressure on the lid cylinder. One of the horizontal cylinders presses the scrap against the ejection door of the baler. This door is raised hydraulically after baling is complete. The bundle is then removed from the chamber by horizontal cylinder.

Scrap Feeding: With Small balers, metal may be fed into the press box or chamber manually or by means of a loading hopper – A fairly large bin on the side or front of the boiler. The advantage of hopper is that they can be filled during the baling cycle, which may take a minute or more. The hopper also adds to safety of the operator as manual filing involves greater risk.

Salient Features:

- Option for Hand Lever operated as well as PLC Controlled Scrap Balers

- High Speed & fully automatic Balers can be manufactured

- Equipped with all the safety features

- CE Marking on the balers can also be arranged on extra cost

- Lower energy consumption with increased rate of production

- Requires minimum maintenance

- Reliable hydraulic system & power pack ensured by the use of imported valves of reputed make

- Valves are easily interchangeable

- Lower cost per ton than any other baler

- Ease of operation

- Each Baler is rigorously tested prior to the dispatch

- Third party Inspection can also be arranged

- Spare parts are easily available across the globe

- Heavy duty construction of the balers

- Can be customized as per the specifications of the clients

- Single compact unit mounted over I –Beam (girders)

- Hydraulic Accessories are provided to avoid accident

- No major civil foundation is required

- Replaceable wear resistance plate for long life of the baling chamber

- Shearing blades on the edges of the chamber and door to shear excess and oversize scrap.

- Heat exchanger (optional) for keeping oil cool

Baling Machine Jumbo

This type baler is used to compress waste scraps and it is triple compression

This type baler is used to compress waste scraps and it is triple compression

Salient Features:

- Option for Hand Lever operated as well as PLC Controlled Scrap Balers

- Equipped with all the safety features

- Reliable hydraulic system & power pack ensured by the use of imported valves of reputed make

- Valves are easily interchangeable

- Lower cost per ton than any other baler

- Single compact unit mounted over I –Beam (girders)

- No major civil foundation is required

- Replaceable wear resistance plate for long life of the baling chamber

- Shearing blades on the edges of the chamber and door to shear excess and oversize scrap.

- Heat exchanger (optional) for keeping oil cool.

Triple Action Scrap Baling Machine Turnout

Triple compression balers are used for reducing three dimensions of the scrap material by using hydraulic force from three different angles. The two horizontal cylinders are arranged at right angles to each other. Vertical reduction generally takes place by hydraulic pressure on the lid cylinder. One of the horizontal cylinders presses the scrap against the ejection door of the baler. This door is raised hydraulically after baling is complete. The bundle is then removed from the chamber by horizontal cylinder.

Triple compression balers are used for reducing three dimensions of the scrap material by using hydraulic force from three different angles. The two horizontal cylinders are arranged at right angles to each other. Vertical reduction generally takes place by hydraulic pressure on the lid cylinder. One of the horizontal cylinders presses the scrap against the ejection door of the baler. This door is raised hydraulically after baling is complete. The bundle is then removed from the chamber by horizontal cylinder.

Scrap Feeding: With Small balers, metal may be fed into the press box or chamber manually or by means of a loading hopper – A fairly large bin on the side or front of the boiler. The advantage of hopper is that they can be filled during the baling cycle, which may take a minute or more. The hopper also adds to safety of the operator as manual filing involves greater risk.

Salient Features:

- Option for Hand Lever operated as well as PLC Controlled Scrap Balers

- High Speed & fully automatic Balers can be manufactured

- Equipped with all the safety features

- CE Marking on the balers can also be arranged on extra cost

- Lower energy consumption with increased rate of production

- Requires minimum maintenance

- Reliable hydraulic system & power pack ensured by the use of imported valves of reputed make

- Valves are easily interchangeable

- Lower cost per ton than any other baler

- Ease of operation

- Each Baler is rigorously tested prior to the dispatch

- Third party Inspection can also be arranged

- Spare parts are easily available across the globe

- Heavy duty construction of the balers

- Can be customized as per the specifications of the clients

- Single compact unit mounted over I –Beam (girders)

- Hydraulic Accessories are provided to avoid accident

- No major civil foundation is required

- Replaceable wear resistance plate for long life of the baling chamber

- Shearing blades on the edges of the chamber and door to shear excess and oversize scrap.

- Heat exchanger (optional) for keeping oil cool